Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", July 2003, page 13

In the last PIN that appeared in the April 2003 issue of CJ, we talked about

foreign styles made by the R. Thomas & Sons Co. You may recall, the 1925

American Jobbers Supply Co. catalog showed five styles including a

"gingerbread man". All of these were made of dry process porcelain.

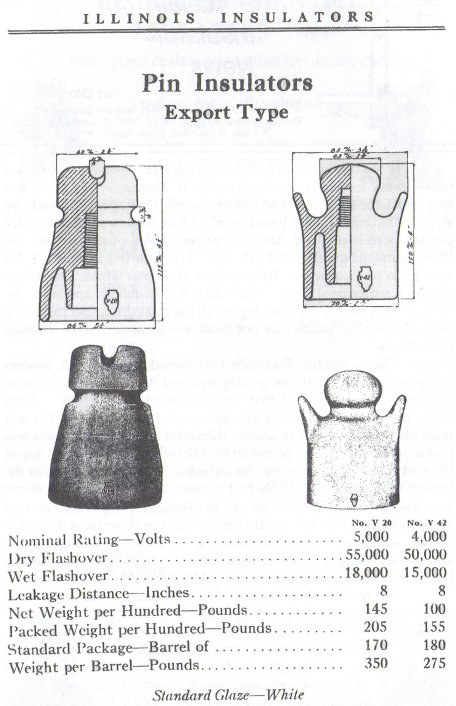

Paul Axman sent me copies of pages from the Illinois catalog No. 103 dated July

1927. The same five insulator styles are shown on two pages. The standard glaze

was white. One of the pages is reproduced here. Note that the insulators appear

to be marked with the Illinois' map logo with the catalog number inside the map.

Naturally, Illinois did not mark the insulators since Thomas made them.

Illinois

Electric Porcelain Co. started making wet process porcelain in 1915. That line

quickly replaced their dry process line of insulators started in 1910 that was

embossed "MACOMB". They stopped making dry process insulators some

time in the 1920's and most likely around 1920 or shortly thereafter. Illinois

production was probably all wet process porcelain by 1925 when they installed

one of the first tunnel kilns used by the industry. To be competitive in the

foreign market, they probably had to use cheaper dry process porcelain, and

contracted this work out to Thomas. We have confirmed Thomas made all the known

dry process foreign styles from the group of five. Illinois cataloged them using

a "V" with the catalog number to designate another manufacturer. And

Illinois also sold the foreign line of insulators through American Jobbers

Supply Co.

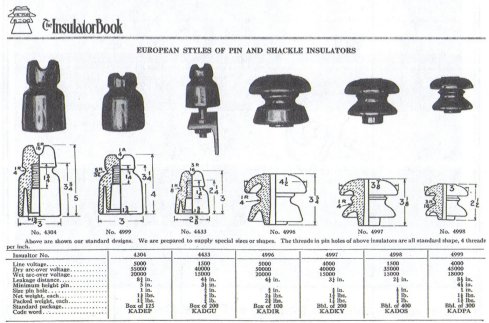

Thomas was not the only U.S. company to make pin-type insulators for

the foreign market. Locke introduced three small foreign style insulators and

three shackle insulators in their 1916 catalog. This line continued unchanged

through their 1925 catalog and was dropped for the 1927 catalog. They also

offered European style "gooseneck" or hook-shaped steel pins for

mounting on the side of a pole as was and still is common in Europe.. While the

Illinois styles did not indicate a pinhole size, the Locke styles indicated four

threads per inch with a 1" pinhole for the largest size and _" pinhole for

the two smaller ones. I'm not familiar with foreign pinhole sizes but believe

the 1" pinhole seems a bit odd for foreign insulators. Note, too, that all

the European style insulator illustrations in the Locke catalog appear to be

brown glazed. You might check the unmarked brown-glazed foreign insulators in

your collection to see if they are similar to the ones Locke produced from 1916

to 1925. What makes the identification difficult is the Locke European styles

were made of wet process porcelain as were those produced in England, Germany,

and other European countries.

Page from Illinois catalog No. 103 dated July 1927.

This time period must have been a time of

particularly fast growth in European countries. Maybe it had something to do

with WW I, which could have dramatically reduced insulator production from

England and most probably Germany. You may recall that Fred Locke, too, was

having glass insulators made at Corning using his patented glass formulas that

were similar to Pyrex, and he was trying to sell insulators to a company in

Italy. Of course, Fred Locke's insulators for Italy were suspension insulators

for high voltage transmission work. The smaller telephone style insulators

produced by Thomas and Locke probably had more to do with loss of production

capacity as the result of the war.

From the 1919 Locke catalog.

The Illinois catalog also showed very similar shackle insulators but did not

carry the "V" catalog notation and the insulators were probably made

of wet process porcelain at the Illinois factory.

The LSIC had a great

get-together at Marilyn and Bill Albers' ranch last weekend with a swap meet and

excellent barbeque with all the trimmings. In Marilyn's collection I found one

of the brown Thomas twist-lock insulators pictured at the bottom of page 41 in

April CJ. The sticker said it came from Mike Guthrie. So at least two specimens

are known. These were made by Thomas of dry process porcelain. I also

photographed a white twist-lock insulator in Marilyn's collection that was crude

enough to be U.S. made. For some reason, the illustration and discussion of this

unusual style was inadvertently left out of the PIN article in April CJ.

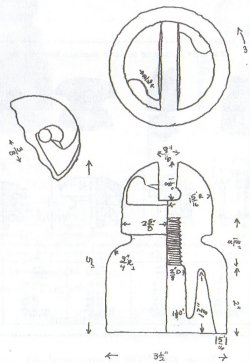

The

Ohio Brass Co. made this style of twist-lock and called it the "Cuban

Type". I feel certain that Ohio Brass made Marilyn's white insulator. Jack

Tod found a blueprint at the Ohio Brass factory that was dated April 20, 1908.

It did not reproduce very well, but hope you can see enough of it to tell what

it is reproduced here. The blueprint called for a white glaze. The twist-lock fingers were similar to the Thomas version. I would like to hear from

anyone who has one of the twist-lock designs made by Thomas or Ohio Brass or any

of the foreign styles we discussed earlier.

This blueprint of the "Cuban Type" was found by Jack Tod at the

Ohio Brass factory.

The one on the left is a Thomas dry process twist-lock.

The one on the right

is a "Cuban Type" made by Ohio Brass.

Two more twist-lock insulators. The one on the left has a large raised

button

with CP embossed. I believe the white one is unmarked.

Photos from Marilyn

Albers' Collection.

|